Hazards Identifiion and Risk Assessment in Thermal ...

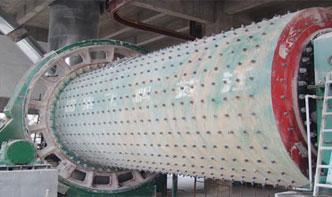

Dec 04, 2014 · As shown in the the thermal power plant has the following area operations: Coal Handling Plant. Coal transported to the plant by the rail line and carrier trucks. This coal is transfer from the underground bunker to crusher by series of conveyer belt. In coal crusher coal size reduced up to ¾ after that coal transfer to the boilers ...