Machine Processing vs. Tolerances

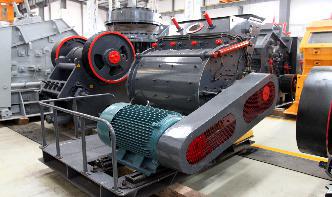

Machine processing and tolerance grades. A tolerance is the total permissible variation of size. where the tolerance is the difference between the limits of size. Range of tolerance grades that various machine processes may produce under normal conditions: ANSI Standard Tolerances are indied in the diagram below: