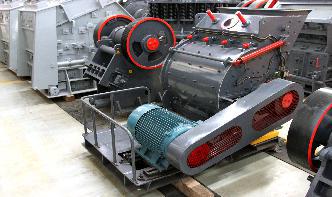

Ball Mill

RETSCH is the world leading manufacturer of laboratory ball mills and offers the perfect product for each appliion. The High Energy Ball Mill E max and MM 500 were developed for grinding with the highest energy input. The innovative design of both, the mills and the grinding jars, allows for continuous grinding down to the nano range in the shortest amount of time with .