Iron Ore

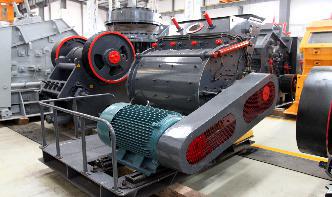

Iron Ore Beneficiation Solutions Across Project Lifecycle. Metallurgical Testing . To be confident in investing in a project, you need to know that the separation process will work on startup and throughout the life of the operation. We give you certainty by testing representative samples and analysing the results beyond basic calculations to deliver innovative and cost effective process ...