GrafGalenStraße 17 industry

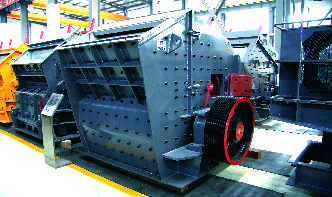

cement clinker production lines. With an overall capacity of 20,000 tons of clinker per day, the new plant will be one of the largest in the country. We are acting as an EPC contractor and also supplying all and also supply all the components for the new lines, from raw material preparation and clinker manufacturing to cement loading. engineering. success. together. Every plant .