Pyrite Mining | Processing Equipment | Flow Chart | Cases ...

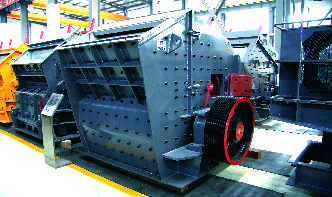

Pyrite mining process, how to extract mineral from rock and placer deposit, related processing plant flow chart and layout design. read more. Skip to content. Menu. ... moss killer, and many other chemical processes. Iron sulfate which comes from .