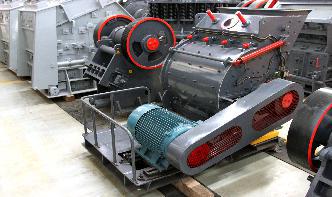

MINING

The company has extensive expertise working on the design and development of coal washing and materials handling plants, iron ore screening and crushing plants, gravel and garnet plants. In addition the company has worked on the detailed design and development of various mechanical and process equipment, such as radial stacking conveyors, curved conveyors, .