Cobalt Ore Mining Process | Equipment | Flow | Cases

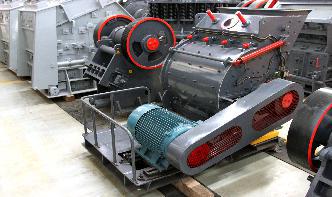

Cases Study Cobalt Ore Mining. Raw mineral description: Mineral composition: copper % and don't kown the cobalt content. Customers requirements: the lead and barite grade should reach 2530%. The concentrate can be a coppercobalt mixed concentrate. And raw ore only needs to be crushed below 2mm.