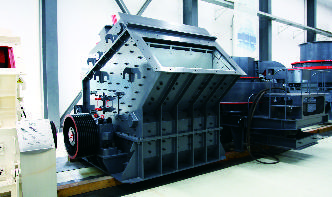

Crusher Blow Bars Material Selection

Nov 09, 2018 · This material is commonly used in recycling industries and primary crushing in quarries. Certain appliions are unsuitable for this material, including limestone crushing and slag recycling. This blow bar consisting of hard ceramic particles on the wear surface in a new martensitic steel matrix.