Coal Preparation and Resource Recycling Plants | Mitsui ...

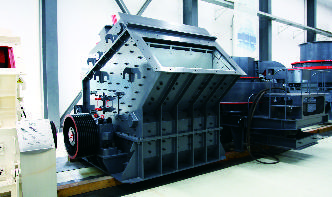

While the coal industry has waned in Japan, Nagata Engineering continues to be the premier source of coal washing technology, and it now manufactures resource recycling plant utilizing its original expertise. This is a unique business that focuses on the words "select" and "separate." Examples include technology to selectively remove ...