5 Gold Extraction Methods to Improve Your Recovery Rate ...

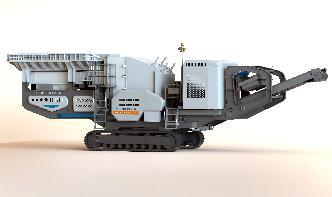

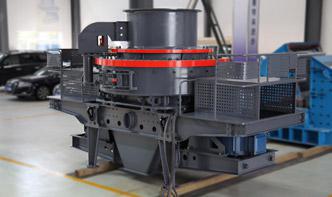

· The gold ore grinding equipment in the grinding stage: ball mill,rod mill. Ⅲ. Beneficiation stage The beneficiation stage is a crucial part of gold extraction during the whole gold ore processing plant. Placer gold mine and rock gold mine are most widely processed to extract gold concentration.