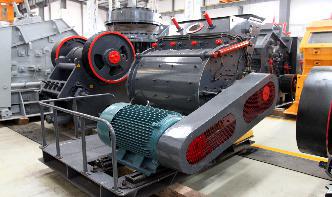

EFFECTS OF GRINDING MEDIA SHAPES ON BALL MILL ...

Spherical grinding media are predominantly used in final stages of ore grinding. The spherical balls change shape through breakage and wear. Though this is universal in milling, its contribution and effect on milling kinetics, load behaviour and mill power is not fully established. One area that is usually ignored is the relationship between