Different grinding process of nano mill_Franli Machine

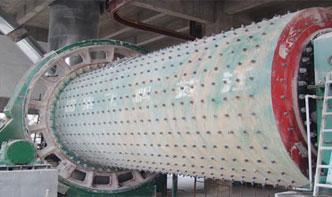

It ranges from rough crushing to wet grinding for getting a proper idea of the techniques involved in the process of milling and grinding that may be the right for your end uses. Materials as well as the size goals of the particles as you look out for the range of milling methods offered with the help of the nano mill.