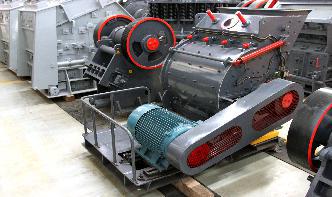

Sizes Of Conveyor Belt For Rock Crushing

The Conveyor Belt Crusher Rental Amp Sales. There are many sizes available, so just call if you need a conveyor for your aggregate and recycling needs. Categories Aggregate Materials, Facts, Rock Crushing Equipment By February 1, 2018 Tags aggregate equipment utah crusher rental rock crusher for rent utah rock crusher rental utah. Get Price