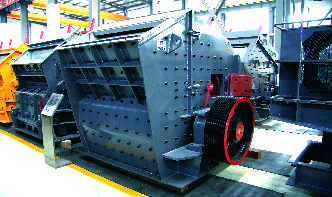

Jaw crusherSinonine

PE/PEX Series Jaw Crushers is of single toggle type with features of simple structure, easy maintenance, stable function, low operation cost, great crushing ratio. It is used widely in mine, metallurgy, construction, road, railway, hydroelectric, and chemistry. It is suitable for the primary or secondary crush of large rock with compressive ...