raw mill separator drag force

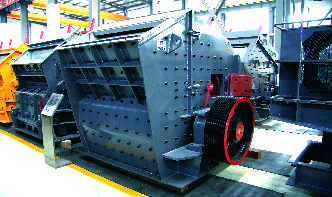

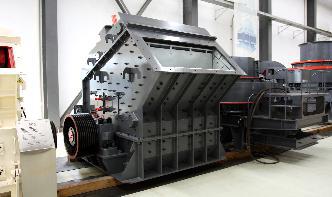

Raw material silos Vertical roller mill Homogenization silo Raw material handling Clinker production Electrostatic precipitator Separator Finish mill. 5 The entire cement manufacturing process producing up to 12,500 tons of clinker a high level of power and force not only completely reliable, but also extremely energyefficient.