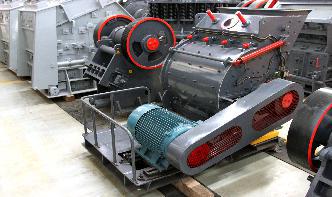

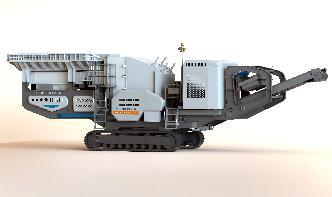

rock sand manufacturing process

rock sand manufacturing process Coal Surface Mining . rock sand manufacturing process Description : rock sand manufacturing process flow chart – 2 Aug 2013 . More details: Get the price of machines: Shanghai shibang. Get Price Here! synthetic sand manufacturing in india Shanghai Xuanshi ...