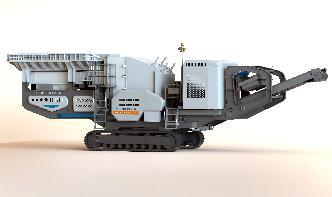

gold raymond mill for gold ore grinding

china made rock gold ore dressing equipment grinding mill. Ball Mill for Gold Ore, Rock, Copper, Cement Grinding China Raymond Mill Stainless Steel Pepper Mill Trapezium Mill China Grinder Ball Milling Machine Raw Material Get Price And Support Online, If you want to learn more about our Crushers and Industrial grinding mills, Gold Ore Copper ore Other: Message: .